Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

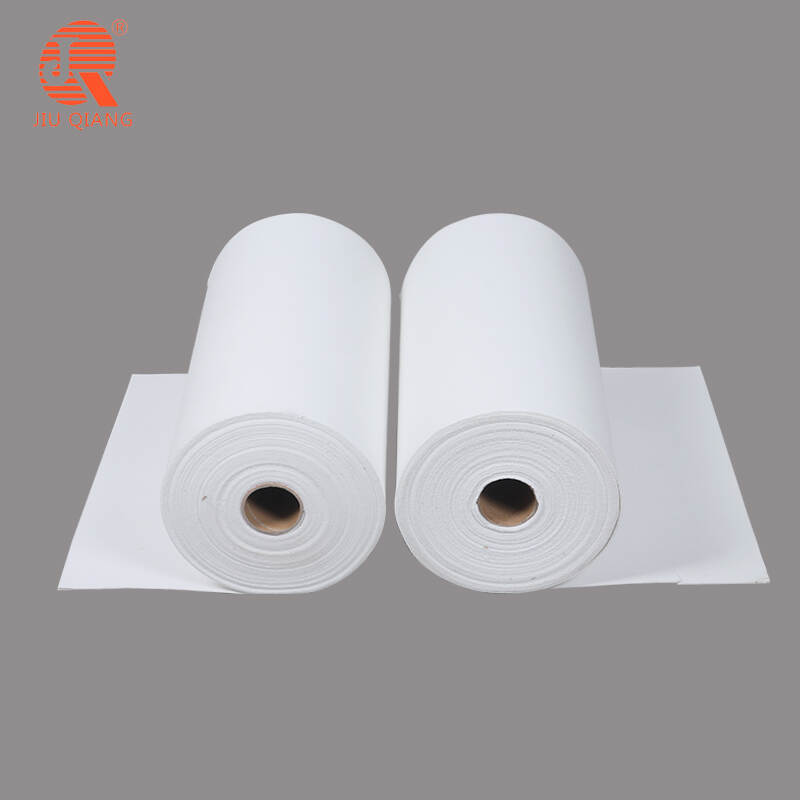

Practical Uses of Ceramic Fiber Paper in Industry and Daily Applications

In industries where high temperatures and thermal insulation are critical, materials that can withstand extreme environments play a key role. Among them, ceramic fiber paper has become a preferred choice thanks to its lightweight, flexible, and heat-resistant properties. Whether used in furnace linings, electrical insulation, or sealing applications, ceramic fiber paper offers reliable performance that benefits both industrial operations and specialized projects.

What Is Ceramic Fiber Paper?

Ceramic fiber paper is a lightweight refractory product made from high-purity alumino-silicate fibers. It is manufactured through a carefully controlled process of blending fibers with binders, producing a paper-like material that is thin, flexible, and easy to cut. Despite its light structure, it maintains excellent thermal stability, low heat conductivity, and resistance to thermal shock.

This unique combination makes it suitable for applications where space is limited, but high-performance insulation is required.

Key Features of Ceramic Fiber Paper

Before looking into its applications, it’s important to highlight why industries choose ceramic fiber paper:

-

High-temperature resistance (up to 1260°C / 2300°F depending on grade)

-

Low thermal conductivity, reducing energy loss

-

Lightweight and flexible, easy to cut and shape

-

Good dielectric strength, useful in electrical insulation

-

Chemical resistance, stable against most corrosive agents except strong alkalis and hydrofluoric acid

These properties give ceramic fiber paper a wide range of uses across multiple industries.

Common Industrial Uses of Ceramic Fiber Paper

1. Furnace and Kiln Insulation

Ceramic fiber paper is widely used in furnace linings, kiln insulation, and heating equipment. Its thin profile makes it an excellent back-up insulation or gap filler where rigid materials cannot fit. This improves energy efficiency and extends the life of refractory linings.

2. High-Temperature Gaskets and Seals

Because it can withstand intense heat and pressure, ceramic fiber paper is commonly cut into gaskets, seals, and packing materials for high-temperature equipment. Industries like petrochemical, steel, and power generation often rely on it to maintain airtight seals in extreme conditions.

3. Electrical Insulation

With strong dielectric properties, ceramic fiber paper is used as an insulating material in electrical appliances, heating elements, and thermal switches. It provides both thermal and electrical protection, preventing overheating and short circuits.

4. Automotive Applications

In the automotive industry, ceramic fiber paper is used for exhaust systems, heat shields, and catalytic converter insulation. Its lightweight yet heat-resistant nature helps improve performance and reduce risks associated with extreme exhaust temperatures.

5. Fire Protection and Safety Equipment

Ceramic fiber paper is also used in fireproof barriers, protective clothing, and safety equipment. Its ability to resist high heat makes it suitable for fire protection panels, welding blankets, and fire curtains.

Benefits of Using Ceramic Fiber Paper

-

Energy savings: reduces heat loss in industrial processes.

-

Durability: resists wear and tear even in extreme heat.

-

Versatility: easy to cut and mold for custom applications.

-

Safety: provides both thermal and electrical protection.

Conclusion

Ceramic fiber paper may look lightweight and fragile, but it is an indispensable material in industries requiring high-temperature insulation and protection. From furnace linings and electrical insulation to automotive exhaust systems and fireproof equipment, its applications are both practical and diverse.

If you are looking for ways to improve thermal efficiency, reduce energy loss, and ensure safety in your operations, ceramic fiber paper is a solution worth considering.